LATEST PROJECTS

Project |04

A miniaturised sensor based on microfluidic platform for caffeine detection from food samples

The present invention provides a low cost miniaturized sensor based on microfluidic platform for caffeine detection from food samples. The device consists of inter-digitized (IDEs) gold electrode sensor with a PMMA well on top for the sample volume requirement in micro liters. It is fabricated using conventional photolithography techniques in a two step process. The prepared sensor has excellent sensitivity for CAF samples, with a detection limit of 0.01 mM L−1. The final product can be formulated in the form of a kit that can be utilized for quantification of various non-toxic caffeine beverages.

Project |05

A comparative study of graphene and MWCNTs for ammonia detection using MEMS based sensor towards point of care application

Multi-walled carbon nanotube (MWCNT) and graphene (G) thin film-based portable, rigid and highly efficient sensor was developed for ammonia (NH3) gas sensing applications. The sensor response as a function of gas exposure time were measured and the data from MWCNT and graphene samples were compared. The notable characteristics of these sensors are fast response time (~30 seconds), and excellent reproducibility with detection level up to 6 ppm, the selectivity of the sensor was also tested by exposing it to IPA and NH3 simultaneously. The potential of this sensor as a low cost, portable and real-time medical breath monitoring device is discussed as well.

Project |06

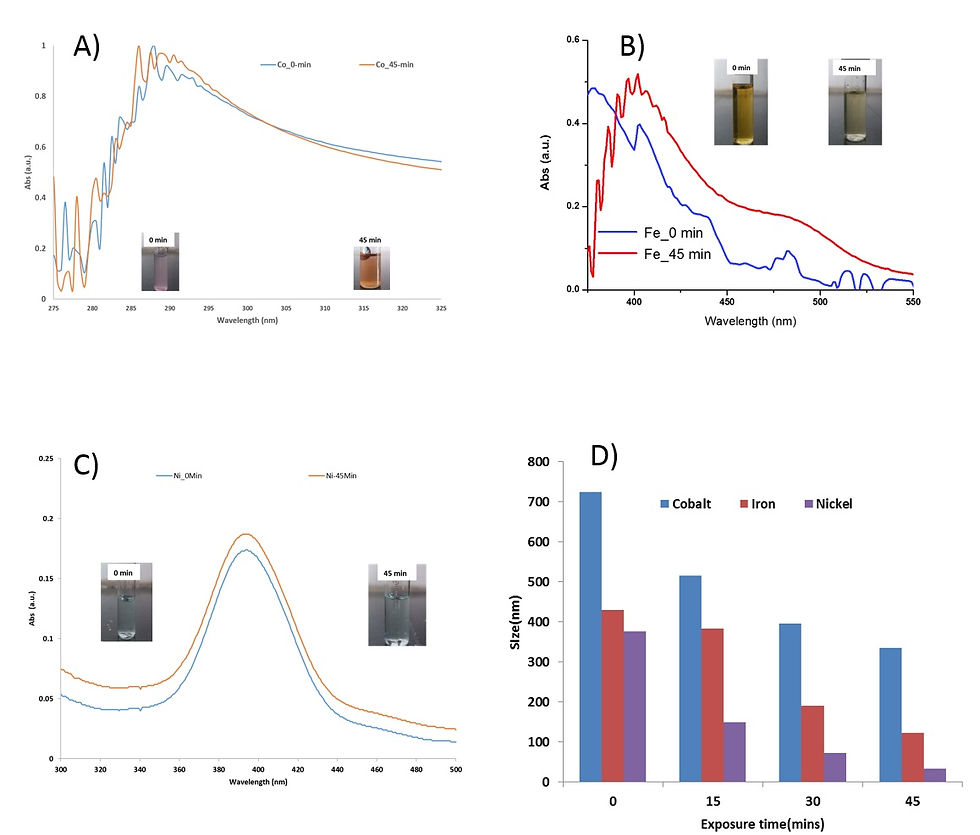

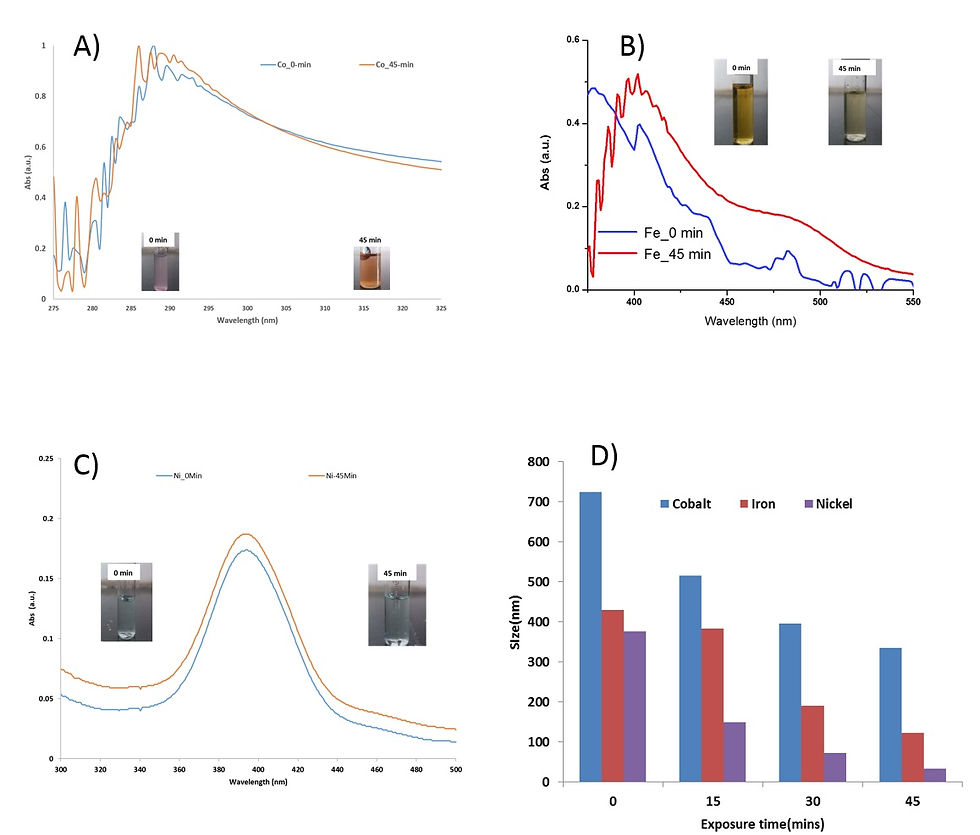

A low-cost and versatile mini-arc plasma system for nanoparticle synthesis via clean technology route

A simple and versatile atmospheric direct current mini-arc plasma source has been developed to produce nanoparticles as small as a few nanometers. Nanoparticles are produced instantly in a period of time once the plasma is ignited. The micro-plasma caused the aqueous metal ions present in the solution to reduce and nucleate into nanoparticles at ambient conditions (room temperature and atmospheric pressure) without presence of any chemical reducing agents. In this work, we synthesized transition metal (Co, Fe, Ni) nanoparticles using plasma method. A 3mM solution was made in distilled water of the corresponding metal salt, then this solution was exposed to plasma for different time intervals. The samples were then characterized by UV-vis, DLS, SEM and AFM. There was a significant decrease in particle size with increasing exposure time. It was found that Iron, cobalt and nickel decreased by 69%, 74% and 90% respectively after 45 minutes of plasma exposure. Hence, the new mini-arc plasma source shows promise to accelerate the exploration of nanostructured materials. The prepared nanoparticles can then be used for various applications such as drug delivery systems, sensors, environmental monitoring etc. The system and method used for the production of nanoparticles is very simple, low cost and can easily be mass produced to meet the industry requirements.

Just a sample of my work. To see more or discuss possible work >>